CO₂ / NH₃ cascade refrigeration: the hybrid solution for sites with high thermal loads

/0 Comments/in blog /by webdono19In industrial or commercial settings where refrigeration requirements are high – large-capacity cold rooms, freezing areas, multi-storey systems, massive heat flows to be removed – CO₂/NH₃ cascade refrigeration is increasingly emerging as a high-performance, reliable and environmentally friendly hybrid solution. At Frigotec, we support operators of large retail outlets, warehouses, food processing plants and logistics companies in Belgium in the implementation of CO₂/NH₃ cascade refrigeration systems adapted to their thermal load constraints, European standards and energy efficiency requirements.

CO₂/NH₃ cascade refrigeration combines the advantages of natural CO₂ (R744) in the low-temperature loop and natural NH₃ (ammonia – R717) in the high-temperature loop, via a cascade exchanger. This configuration optimises cooling efficiency, reduces the environmental footprint (very low global warming potential for CO₂ and NH₃) and meets the high thermal loads found at high-activity sites. Studies show that NH₃/CO₂ cascade systems are particularly effective for low and very low temperature applications.

In this document, we review the fundamentals of CO₂/NH₃ cascade refrigeration, its advantages, constraints, selection criteria, implementation steps for a site with a high thermal load, and specific Belgian considerations. Frigotec invites you to follow this guide to understand why and how to choose a CO₂/NH₃ cascade refrigeration solution.

Understanding CO₂ / NH₃ cascade refrigeration

A. Operating principle

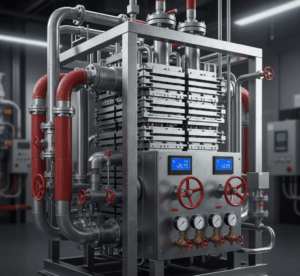

The principle of CO₂ / NH₃ cascade refrigeration is based on two separate refrigeration circuits connected via a cascade heat exchanger:

- A high-temperature circuit using ammonia (NH₃) fluid → it ensures the condensation of the low-temperature circuit fluid.

- A low-temperature circuit using CO₂ (R744) fluid → it captures the heat to be removed from the process or cold room.

In this setup, CO₂ circulates in the cold section (evaporator, expansion, compression) and releases its heat into the cascade exchanger, where NH₃ absorbs this heat and then releases it into the environment or an external condenser. This coupling allows the optimal thermodynamic properties of each fluid to be used in the temperature ranges for which they are most efficient.

B. Why “cascade”?

The term “cascade” in CO₂/NH₃ cascade refrigeration means that the two circuits are in thermal cascade: the condenser of the low-temperature circuit (CO₂) becomes the evaporator of the high-temperature circuit (NH₃). This arrangement is described as typical of cascade cycles with multiple compression stages.

C. Why CO₂ + NH₃?

This combination is particularly relevant for sites with high thermal loads because:

- CO₂ has a low global warming potential (GWP) and is non-toxic, making it easy to install in busy areas.

- NH₃ is extremely effective as a condensing fluid and offers excellent efficiency for the high-temperature loop.

- The combined system reduces the amount of toxic refrigerant in occupied areas by confining NH₃ to the technical room and leaving only CO₂ (a safer refrigerant) in the areas to be air-conditioned.

Thus, CO₂ / NH₃ cascade refrigeration is a hybrid solution that combines energy efficiency, environmental friendliness and adaptability to heavy industrial constraints.

Key advantages of CO₂ / NH₃ cascade refrigeration for sites with high heat loads

A. High energy efficiency

CO₂/NH₃ cascade refrigeration offers superior energy performance: typically, systems using NH₃ combined with CO₂ in cascade are “extremely efficient for low and very low temperature applications (below –40 °C)”.

Furthermore, parametric studies show that the use of a high-performance internal exchanger in the NH₃/CO₂ assembly reduces irreversibilities and thus improves efficiency.

B. Reducing the environmental footprint

By opting for a CO₂ / NH₃ cascade refrigeration system, natural refrigerants are used: NH₃ and CO₂. NH₃ has a GWP of zero and an ozone depletion potential of zero. This enables compliance with European and Belgian regulations on refrigerants and anticipates the replacement of HFCs with a high global warming potential.

C. Suitable for high thermal loads

For sites with a “high thermal load” — i.e. where there is a lot of heat to extract, large temperature differences to maintain, or intensive cycles (e.g. freezing at -40°C, cold rooms, freezers, logistics facilities) — the CO₂/NH₃ cascade refrigeration solution is designed to meet these constraints. It reliably achieves low temperatures and distributes the load between two circuits, which limits overheating, rapid cycles, and excessive consumption.

D. Enhanced security and flexibility of installation

By combining CO₂ (in the conditioned area) and NH₃ (in the technical room), the amount of ammonia present in occupied spaces is limited, thereby enhancing safety. Modular plug-and-play cascade systems are now available.

In Belgium, this flexibility is an asset because sites are often segmented, with significant spatial and regulatory constraints.

E. Reliability and durability

CO₂/NH₃ cascade refrigeration systems use robust components, dedicated heat exchangers and specialised compressors for NH₃ and CO₂, ensuring a long service life. Technical studies confirm their long-term stability.

Specific considerations when choosing a CO₂ / NH₃ cascade refrigeration solution

A. Define the thermal load and usage profile

Before embarking on a CO₂ / NH₃ cascade refrigeration solution, it is important to understand:

- The maximum heat load to be removed (in kW or cooling tons) – for example, number of cold rooms, volume, frequency of opening, air infiltration, heat emissions.

- The required temperature profile (low, medium, very low temperature): for example, freezing at –40°C, pre-cooling at –20°C, storage at +2°C.

- The number of operating hours, the number of peak periods (e.g. in winter/summer), and the gradual thermal load increase.

Proper sizing is crucial to avoid oversizing (unnecessary investment) or undersizing (poor performance).

B. Choice of fluid and operating pressures

In a CO₂ / NH₃ cascade refrigeration system, the two fluids are:

- NH₃ (ammoniac) – circuit haute température. Il est efficace, mais requiert des mesures de sécurité spécifiques (toxique, inflammable dans certaines concentrations).

- CO₂ (R744) – low-temperature circuit. It operates at high pressure, which requires suitable components.

The adjustment of pressures, heat exchange in the cascade exchanger, and the temperature difference between the two circuits are essential elements. A study indicates that optimising these parameters (e.g. CO₂ evaporation temperature at –10 °C) can significantly improve efficiency.

C. Location and regulatory constraints

In Belgium (and Brussels), the following must be taken into account:

- European and Belgian standards relating to natural refrigerants and the safety of NH₃ installations (in technical rooms, ATEX zones, etc.).

- The location constraints of NH₃ compressors (often in a separate engine room) and CO₂ pipes (high pressure).

- Health and safety requirements – particularly in the food industry, where the installation of a CO₂/NH₃ cascade refrigeration system often requires coordination with HACCP standards, DNF (Directorate-General for Agriculture, Food and Forestry) inspections, etc.

- The possible need to compartmentalise the technical room and install ammonia or CO₂ detectors. For example, in an NH₃/CO₂ cascade installation, a sensor detects CO₂ leaks in the NH₃ section to prevent the formation of corrosive crystals.

D. Investment budget & return on investment

Choosing CO₂/NH₃ cascade refrigeration requires a higher investment than a traditional refrigeration system (HFC, HFC/HFO): specialised components (compressors, heat exchangers, high-pressure piping), design offices, installation. However:

- Increased energy savings (lower consumption, greater efficiency) improve return on investment.

- Sustainability (less future recovery anticipated to comply with regulations) is an advantage.

- In Belgium, where energy and refrigerant taxes are high, opting for a natural and efficient solution such as CO₂ / NH₃ cascade refrigeration is becoming a competitive strategy.

E. Maintenance, safety and training

The installation of a CO₂ / NH₃ cascade refrigeration solution involves:

- Regular and specialised maintenance (NH₃ compressors, high-pressure CO₂ circuits, cascade exchanger);

- Increased safety vigilance (detectors, ventilation, containment) for the NH₃ circuit;

- Training maintenance staff and operators in the specific characteristics of natural fluids and high pressures.

Frigotec offers maintenance contracts tailored to cascade installations to ensure longevity and consistent performance.

Steps for implementing a CO₂ / NH₃ cascade refrigeration solution

A. Pre-conceptual study and dimensioning

At Frigotec, support begins with an on-site assessment:

- Assessment of refrigeration requirements, heat flows, target temperatures, stored mass and planned openings.

- Analysis of available space, access to technical rooms, possibility of partitioning, height or roof constraints, etc.

- Recognition of Belgian requirements (regulations, permits, ATEX zone, etc.).

- Proposal for a technical diagram of a CO₂ / NH₃ cascade refrigeration system, including load calculations, choice of fluids, return on investment estimate, and selection of suitable equipment.

B. Detailed design and component selection

Next, the dimensions are specified:

- Selection of NH₃ and CO₂ compressors, adapted to the load, the desired temperature, and suitable for intensive operation.

- Choice of cascade exchanger (plate, helix, coil tube), exchange technology plays a key role in performance.

- Determination of evaporation/condensation pressures, NH₃ condensation temperature, CO₂ evaporation temperature.

- Selection of safety devices (NH₃ and CO₂ detectors, alarms, forced ventilation), compatible materials (stainless steel, high-pressure steel for CO₂).

- Engineering of high-pressure piping, pumps for liquid CO₂, automated controls.

C. Installation and commissioning

The installation of a CO₂ / NH₃ cascade refrigeration solution involves the following steps:

- Installation of the NH₃ technical room (compressors, condenser, safety equipment);

- Assembly of the CO₂ circuit (evaporators, pump if required, high-pressure piping);

- Installation of the cascade heat exchanger between the two circuits;

- Electrical connection, automation controls, instrumentation (pressure sensors, temperature sensors, etc.);

- Commissioning and adjustment: thermal balancing, flow control, safety line testing.

During this phase, Frigotec ensures that the CO₂ / NH₃ cascade refrigeration solution complies with Belgian standards and operating requirements (hygiene, safety).

D. Daily operation and maintenance

To ensure that the CO₂ / NH₃ cascade refrigeration solution operates optimally:

- Frigotec recommends continuous monitoring of temperatures, pressures and energy consumption.

- A preventive maintenance schedule is implemented: checking compressors, cleaning heat exchangers, checking NH₃/CO₂ detectors, checking high-pressure seals, observing CO₂ pipes.

- In the event of an alarm (pressure variation, detection of NH₃ or CO₂), the rapid response protocol must be implemented.

- Continuous optimisation (e.g. adjusting the NH₃ condensation temperature according to the season, managing the liquid CO₂ pump) improves the efficiency of CO₂/NH₃ cascade refrigeration.

E. Optimisation and scalability

One advantage of such a solution is its scalability:

- Plan for future growth: install a power plant that is sized for current needs but can be scaled up.

- Add additional cold rooms, or convert part of the facility to deep freezing.

- Integrate smart remote monitoring, mobile alarm and energy data analysis functions for CO₂ / NH₃ cascade refrigeration.

Adapt the system to new constraints (e.g. heat recovery for preheating, use of CO₂ as a secondary fluid) to maximise ROI.

Why choose Frigotec for your CO₂ / NH₃ cascade refrigeration system?

At Frigotec, we have developed expertise in CO₂ / NH₃ cascade refrigeration solutions for sites with high thermal loads in Belgium. Here is what we offer:

- Comprehensive support: from study to commissioning, including design, installation and maintenance.

- Expertise in Belgian and European standards relating to natural refrigerants, NH₃ safety, and hygiene requirements.

- Customised CO₂ / NH₃ cascade refrigeration solutions, tailored to your actual needs, with return on investment analyses and energy optimisation.

- A network of technicians trained and certified in CO₂, ammonia, and high thermal load installations.

- Customised maintenance contracts, including supervision, energy reporting, technological updates (smart control, performance).

Thanks to Frigotec, your investment in CO₂ / NH₃ cascade refrigeration becomes a strategic asset: you improve your performance, respect the environment, and prepare for the future.

Typical application: a logistics warehouse in Brussels

Imagine an agri-food logistics warehouse located in Brussels, with:

- freezer rooms at –30°C for frozen foods;

- storage rooms at +2 °C for fresh produce;

- a significant flow of goods, frequent opening of doors, high thermal load due to hot aisles and equipment.

In such a context, CO₂ / NH₃ cascade refrigeration is particularly suitable:

- The CO₂ circuit optimises low temperature processing (–30°C).

- The NH₃ circuit efficiently discharges condensation heat, even under heavy loads.

- The separation of technical areas (NH₃ in a secure technical room, CO₂ in cold rooms) minimises risks and facilitates maintenance.

- The increased performance makes it possible to eliminate or reduce redundant systems, optimise space and reduce energy losses.

- Thanks to Frigotec’s monitoring and maintenance, the installation remains efficient in the long term, with a clearly assessed ROI.

The challenges and constraints of CO₂ / NH₃ cascade refrigeration

Although very promising, CO₂/NH₃ cascade refrigeration presents certain challenges:

A. Technical complexity

The management of two circuits, a cascade exchanger, high pressures (CO₂) and safety constraints (NH₃) requires rigorous design, suitable components and careful installation. One study highlights: “The high-temperature circuit (NH₃) and the low-temperature circuit (CO₂) are separate, with each system comprising a compressor, condenser, expansion valve and evaporator. These two circuits are in thermal contact via a heat exchanger…”

B. High pressures and safety

CO₂ operates at pressures much higher than traditional systems, requiring reinforced components, high-pressure piping and specific safety controls. Similarly, ammonia is toxic and flammable at certain concentrations, so safety standards must be observed.

C. Higher initial investment

Compared to a standard refrigeration system, CO₂/NH₃ cascade refrigeration requires a higher initial investment, which may deter some decision-makers. It is crucial to properly size the system and demonstrate the return on investment.

D. Specialised maintenance

Maintaining such a system is more complex and requires trained personnel, rigorous maintenance plans, and increased vigilance. Ignorance or negligence can compromise performance or safety.

E. Climatic conditions and local adaptation

Even though studies prove its effectiveness in hot climates, the installation must be adapted to Belgian conditions, ventilation, heat recovery, seasonal variations, etc. A parametric study in a tropical climate shows that the optimal interface temperature is around –10 °C for CO₂.

Trends and future developments in CO₂ / NH₃ cascade refrigeration

A. Modularity and turnkey solutions

There has been an increase in the number of modular packaged units incorporating CO₂/NH₃ cascade refrigeration, ready to install, with integrated supervision, electronic control and optimisation.

B. Optimisation through AI and advanced supervision

CO₂/NH₃ cascade refrigeration systems can benefit from data analysis and algorithms to optimise performance, detect anomalies and reduce consumption. An analysis study using neural networks applied to CO₂/NH₃ shows accurate monitoring of influencing factors.

C. Spotlight on the environment and regulations

With European regulations (F-gas, natural fluids) and the emphasis on sustainability, CO₂ / NH₃ cascade refrigeration is positioning itself as a solution for the future. Manufacturers are focusing on “green” systems.

D. Energy integration (heat recovery, coupling with heat pump)

A strong trend is the recovery of NH₃ condensation heat for space heating, domestic hot water or preheating, which increases the overall efficiency of the CO₂ / NH₃ cascade refrigeration system and improves the economic balance.

CO₂/NH₃ cascade refrigeration is much more than just a technical alternative: it is a strategic solution for sites with high thermal loads, particularly in Belgium and Brussels, where energy, environmental and regulatory requirements are high. It combines efficiency, environmental friendliness, adaptability to intensive needs and sustainability.

By choosing Frigotec as your partner, you benefit from support designed to get the most out of CO₂ / NH₃ cascade refrigeration, from the initial study to regular maintenance and continuous optimisation. We are convinced that this type of system will quickly become standard in large refrigeration installations in Belgium and Europe.

If you would like to learn more about this topic, obtain a quote or analyse your installation, please do not hesitate to contact us. Together, we will implement a CO₂ / NH₃ cascade refrigeration solution that meets your requirements, improves your performance and secures your future.

Leave a Reply

Want to join the discussion?Feel free to contribute!