Predictive Maintenance of Refrigeration Systems: the Future of Professional Refrigeration

/0 Comments/in blog /by webdono19In a context where requirements for energy performance, food safety, and sustainability are becoming stricter in Belgium, predictive maintenance of refrigeration systems is emerging as an essential revolution. Far from being a mere technological concept, it now represents a concrete and effective strategy enabling supermarkets, food industries, restaurants, pharmacies, hospitals, and logistics warehouses to optimize their facilities while significantly reducing operating costs.

In Brussels, Wallonia, and Flanders, more and more companies are choosing to adopt this innovative approach to prevent breakdowns, ensure the continuity of the cold chain, and meet the strictest European standards.

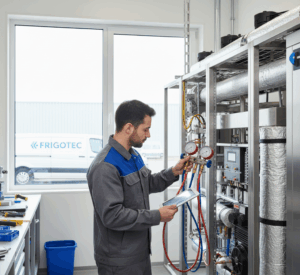

In this article, Frigotec, a recognized specialist in professional refrigeration in Belgium, explains why the predictive maintenance of refrigeration systems represents the future of professional refrigeration, how it works, and what concrete benefits it offers professionals across all sectors.

What is Predictive Maintenance of Refrigeration Systems?

The predictive maintenance of refrigeration systems is a modern method that allows anticipating breakdowns before they actually occur. Unlike corrective maintenance (intervening after a breakdown) or classic preventive maintenance (intervening according to a regular schedule), predictive maintenance uses real-time data to continuously monitor the condition of equipment.

Thanks to smart sensors, data analysis, artificial intelligence, and connected tools, refrigeration systems can now “self-diagnose” and report the slightest anomaly before it impacts the installation’s performance.

This innovative approach allows for early detection of:

- a pressure drop,

- excessive energy consumption,

- an overheating compressor,

- a lack of refrigerant,

- a fan losing efficiency,

- condenser fouling.

For Frigotec, the predictive maintenance of refrigeration systems constitutes a strategic pillar in the evolution of professional refrigeration in Brussels and throughout Belgium.

Why Predictive Maintenance of Refrigeration Systems is Essential in Belgium

Belgium, with its varied climatic conditions, strict standards, and particularly demanding market, is an ideal ground for implementing innovative professional refrigeration solutions. Several reasons explain the rapid rise of predictive maintenance of refrigeration systems in the country.

A. Meeting European and Belgian Standards

The food, medical, and logistics sectors are subject to strict regulations, including:

- European Regulation 852/2004 (food hygiene),

- the HACCP standard, mandatory for supermarkets and food service businesses,

- European energy directives,

- environmental obligations related to refrigerants.

Thanks to continuous monitoring, predictive maintenance of refrigeration systems ensures permanent compliance with critical temperatures, defrost cycles, pressures, and humidity levels, guaranteeing perfect conformity with current standards.

B. Controlling Energy Costs

In Belgium, electricity bills are among the highest in Europe.

However, a poorly maintained refrigeration system can consume up to 30% more energy.

The predictive maintenance of refrigeration systems allows for:

- detecting micro-leaks of fluid that increase consumption,

- analyzing abnormal compressor behavior,

- identifying overly frequent defrost cycles,

- optimizing regulations,

- avoiding cold losses due to poorly closed or insulated display cases.

Frigotec supports numerous supermarkets and industries in Belgium to sustainably reduce their energy consumption through these smart technologies.

C. Ensuring Cold Chain Continuity

A professional refrigerator breakdown in a supermarket or a negative cold room in a bakery can cause:

- total product loss,

- health risks,

- temporary business closure,

- a deterioration of customer image.

With predictive maintenance of refrigeration systems, these situations are avoided, as anomalies are detected several days, sometimes even several weeks, before they generate an actual breakdown.

D. Addressing Ecological Challenges

Reducing the carbon footprint has become an imperative in Belgium.

An optimally used and well-maintained refrigeration system has a longer lifespan and consumes less, which reduces:

- CO₂ emissions,

- refrigerant leaks,

- parts replacement costs.

Therefore, predictive maintenance of refrigeration systems fits perfectly within Belgian and European environmental objectives.

How Does Predictive Maintenance of Refrigeration Systems Work?

The predictive maintenance of refrigeration systems relies on several complementary technologies.

A. Connected Sensors (IoT)

Modern refrigeration installations are equipped with smart sensors that continuously measure:

- temperature,

- humidity,

- pressure,

- compressor vibrations,

- fan speed,

- electricity consumption,

- condenser cycles,

- door openings.

This data is sent in real-time to a centralized platform managed by Frigotec.

B. Data Analysis (Big Data)

The collected data is continuously analyzed to detect the slightest abnormal variation.

Example:

A slight increase of 0.5 bar in compressor pressure can indicate a future refrigerant circulation problem.

C. Artificial Intelligence and Predictive Algorithms

AI compares current data with thousands of scenarios derived from statistical models.

It then predicts potential risks:

- compressor breakdown,

- overheating,

- gas leak,

- condenser fouling,

- fan failure.

D. Instant Alerts

In case of a detected anomaly, Frigotec automatically receives an alert and can intervene immediately or plan targeted maintenance.

Managers can also view all information on smartphones, tablets, or computers.

Concrete Benefits of Predictive Maintenance for Refrigeration Systems

The predictive maintenance of refrigeration systems brings numerous tangible benefits to professionals in Belgium.

A. 60% to 80% Reduction in Breakdowns

The majority of breakdowns are avoided before they occur, ensuring continuous equipment availability.

B. Reduction in Food Losses

In a supermarket, the loss of a single refrigerated display unit can cost several thousand euros.

Thanks to predictive maintenance, these losses are almost entirely eliminated.

C. Significant Energy Savings

An optimally functioning installation can reduce its annual electricity consumption by up to 30%.

D. Extended Equipment Lifespan

Less mechanical stress, less overheating, fewer malfunctions: all these elements extend the lifespan of refrigeration systems by several years.

E. Better Return on Investment

Predictive maintenance transforms maintenance costs into controlled and optimized investments.

Predictive Maintenance of Refrigeration Systems in Supermarkets

Belgian supermarkets (Delhaize, Carrefour, Colruyt, Lidl, independent supermarkets, convenience stores, etc.) are rapidly adopting predictive maintenance of refrigeration systems for several reasons:

- display cases are continuously open,

- compressors operate 24/7,

- cold rooms store sensitive products,

- The slightest breakdown can lead to temporary closure.

Frigotec offers supermarkets tailor-made solutions integrating:

- 24/7 remote monitoring,

- performance data analysis,

- real-time alerts,

- rapid on-site intervention,

- centralized management of all installations.

Frigotec's Expertise: A Key Partner for Successful Retrofitting in Belgium

Successfully transitioning to natural refrigerants requires high-level expertise. The R404A Refrigeration System Retrofit Strategies implemented by Frigotec are based on:

- solid field experience,

- in-depth knowledge of Belgian regulations,

- complete mastery of CO₂ and R290 installations,

- rigorous after-sales service and technical monitoring.

A. Personalized Support

Frigotec operates in:

- supermarkets,

- refrigerated warehouses,

- food businesses,

- hotels and professional kitchens.

Each retrofit project is custom-designed after a detailed audit.

B. Continuous Energy Optimization

After conversion, Frigotec ensures continuous monitoring of the installation via modern supervision systems, further improving efficiency and preventing breakdowns.

C. Long-Term Maintenance

Thanks to its expertise in natural refrigerants, Frigotec guarantees:

- simple and durable maintenance,

- a reduction in emergency interventions,

- increased availability of spare parts.

The predictive maintenance of refrigeration systems, an investment for the future, represents much more than an innovation: it is a profound transformation of how Belgian companies manage their professional refrigeration.

Thanks to this strategy, it becomes possible to:

prevent breakdowns, reduce costs, extend the lifespan of installations, secure the cold chain, reduce ecological impact, and improve operational efficiency.

With Frigotec as a partner, companies across the country can confidently adopt predictive maintenance of refrigeration systems and fully embrace the future of professional refrigeration.

Leave a Reply

Want to join the discussion?Feel free to contribute!