Thermodynamic optimisation of refrigeration plants: how to achieve a COP greater than 5 in the Belgian climate

/0 Comments/in blog /by st oumaimaThe challenge of energy efficiency in Belgian industrial refrigeration: in the current energy context, marked by rising electricity costs and the need to reduce carbon footprints, the thermodynamic optimisation of refrigeration plants has become imperative for Belgian companies. In Brussels, Liège, Ghent and Charleroi, players in the agri-food, pharmaceutical and logistics sectors are now looking for more efficient and sustainable refrigeration solutions.

Achieving a COP (Coefficient of Performance) greater than 5 in the Belgian climate is a major technical challenge. The climatic conditions, characterised by wet winters and moderate summers, require a suitable thermodynamic design. The objective is clear: to maximise the energy efficiency of refrigeration plants while ensuring the reliability and stability of the cooling system.

Frigotec, a recognised specialist in professional refrigeration in Belgium, has established itself as a leading player in this field. Thanks to its expertise, the company supports manufacturers in the thermodynamic optimisation of refrigeration plants, combining advanced engineering, innovative technologies and compliance with European environmental standards.

Understanding the COP and its implications for the Belgian climate

The Coefficient of Performance (COP) is the key measure of the efficiency of a refrigeration system. It expresses the ratio between the useful cooling capacity and the electrical power consumed. For example, a COP of 5 means that for every kilowatt of electricity consumed, the plant produces five kilowatts of cooling.

In the Belgian climate, achieving a COP higher than 5 requires a rigorous approach to thermodynamic optimisation of refrigeration plants. Outdoor conditions, characterised by moderate but variable temperatures, allow for high theoretical efficiency if the system is well designed.

The determining factors include:

- The condensation temperature (influenced by the often humid Belgian ambient air).

- The evaporation temperature (depending on the heat load to be cooled).

- The choice of refrigerant.

- The efficiency of heat exchangers.

- Intelligent compressor control.

Frigotec adapts each refrigeration plant thermodynamic optimisation project to local climatic conditions, combining thermodynamic analyses, energy modelling and practical solutions in the field.

The fundamental principles of thermodynamic optimisation

The thermodynamic optimisation of refrigeration plants is based on a comprehensive approach to the refrigeration cycle. It is not simply a matter of improving an individual component, but of redesigning the entire system to reduce losses and maximise energy exchange.

A. Reduction of temperature differences

The first lever for thermodynamic optimisation of refrigeration plants is to minimise temperature differences between evaporation and condensation levels. The smaller these differences, the higher the COP. In Belgium, where outdoor temperatures often range between 0°C and 25°C, it is possible to condense at lower pressures and achieve a COP greater than 5.

B. Use of variable speed compressors

Frequency converter compressors allow the cooling capacity to be adjusted to actual demand. This modulation significantly improves energy efficiency. Frigotec engineers systematically incorporate this technology into their thermodynamic optimisation projects for refrigeration plants.

C. Optimisation of subcooling and superheating

Precise control of liquid subcooling and gas superheating improves the stability of the refrigeration cycle. This fine regulation is essential to ensure consistent performance and a COP greater than 5.

The choice of refrigerant: a determining factor

Refrigerant is key to energy efficiency. When optimising the thermodynamics of refrigeration plants, the choice of refrigerant directly influences the COP, operating pressure, compatibility with equipment and environmental impact.

A. Natural fluids

Natural fluids such as ammonia (NH₃), carbon dioxide (CO₂) and propane (R290) are preferred in modern power stations. In Belgium, these fluids offer an excellent compromise between performance and sustainability.

- Ammonia (NH₃): ideal for large-capacity industrial installations, it can achieve a COP greater than 5 thanks to its exceptional thermal conductivity.

- CO₂ (R744): suitable for temperate climates such as Belgium, it ensures high efficiency when the cycle is well optimised, particularly in cascade systems.

- Propane (R290): highly efficient for medium-sized systems, it fits perfectly into Frigotec’s energy-efficient solutions.

B. The Frigotec approach

Frigotec favours fluids with low global warming potential (GWP) in all its thermodynamic optimisation projects for refrigeration plants. This sustainable approach is in line with European energy transition objectives, while ensuring above-average efficiency.

Innovative technologies for a COP greater than 5

The thermodynamic optimisation of refrigeration plants relies on continuous technological innovations. These advances not only improve COP, but also reduce maintenance and increase the service life of the installations.

A. Heat recovery

Modern heat recovery systems harness energy from condensation. This heat can be used for space heating, hot water production or industrial processes. In Belgium, this process can reduce overall energy consumption by 20 to 30%.

B. Free cooling et condensation flottante

In the Belgian climate, free cooling (natural cooling using outside air) is particularly advantageous. For much of the year, the ambient temperature allows the condensation pressure to be reduced, thereby increasing the COP.

Frigotec integrates these floating condensation technologies into its systems to maximise the thermodynamic optimisation of cooling plants.

C. High-efficiency heat exchangers

Microchannel heat exchangers and plate condensers offer a larger exchange surface area and reduced heat loss. This equipment, used by Frigotec, actively contributes to achieving a COP greater than 5.

D. Intelligent control and monitoring

Connected control systems enable real-time monitoring of refrigeration plant performance. Thanks to smart sensors, thermodynamic parameters can be adjusted according to actual load, thereby optimising energy consumption.

Case study: the Frigotec approach in Belgium

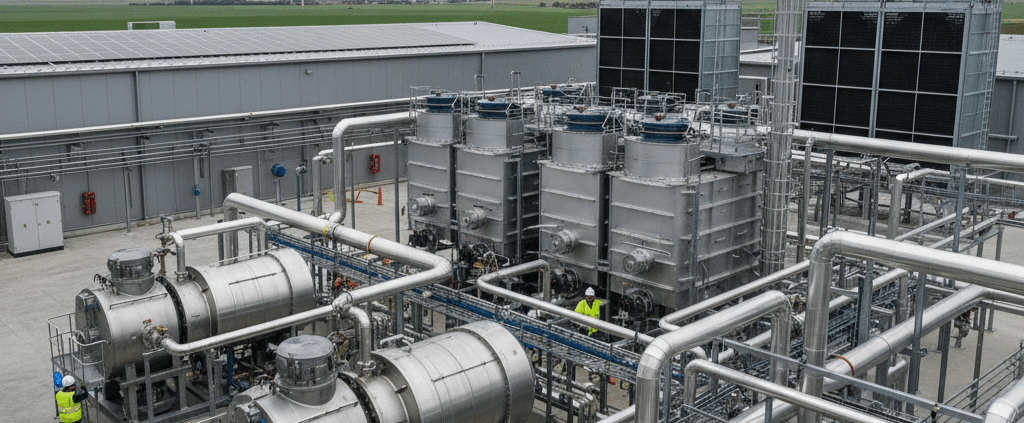

To illustrate the benefits of thermodynamic optimisation of refrigeration plants, Frigotec has carried out several projects in demanding Belgian industrial environments.

A. Logistics platform in Liège

An ammonia plant installed in a fresh produce warehouse has been optimised by Frigotec. Thanks to the addition of a variable speed compressor, a floating condensation system and a microchannel heat exchanger, the overall COP has increased from 3.8 to 5.4.

B. Food industry in Ghent

In a food processing plant, Frigotec implemented thermodynamic optimisation of the transcritical CO₂ refrigeration system. By integrating a parallel cycle and a heat recovery system, the COP was increased to 5.1 while reducing annual electricity consumption by 18%.

C. Cold storage warehouse in Brussels

A mixed system (R290 + CO₂) was designed for a Belgian distribution chain. The thermodynamic study carried out by Frigotec enabled a COP of over 5.2 to be achieved, with a return on investment in less than three years.

Maintenance and monitoring: the key to sustainable performance

The thermodynamic optimisation of refrigeration plants does not stop at the design stage. To maintain a COP above 5, it is essential to ensure rigorous monitoring and appropriate preventive maintenance.

Frigotec offers customised maintenance contracts in Belgium, including:

- Regular cleaning of heat exchangers and condensers.

- Checking operating pressures and subcooling.

- Checking the compressor and refrigerant settings.

- Recalibration of temperature probes and regulators.

A well-maintained power plant maintains its thermodynamic performance, extends its service life and limits energy losses. In addition, Frigotec deploys remote monitoring tools that enable performance indicators to be monitored remotely and action to be taken in the event of an anomaly.

Towards sustainable and intelligent industrial refrigeration

The future of refrigeration in Belgium depends on the convergence of energy efficiency and environmental sustainability. The thermodynamic optimisation of refrigeration plants is fully in line with this dynamic.

The next generations of installations will incorporate:

- Hybrid systems combining heat pumps and refrigeration units.

- Artificial intelligence algorithms capable of self-adjusting the thermodynamic cycle in real time.

- Natural refrigerants with very low GWP.

- Full energy recovery, promoting circularity and carbon neutrality.

In Belgium, Frigotec is playing a leading role in this transformation by developing tailor-made solutions adapted to local market realities and European regulatory requirements.

Belgian expertise in energy efficiency: achieving a COP greater than 5 in the Belgian climate is not a theoretical goal, but a reality made possible by the thermodynamic optimisation of refrigeration plants. By rethinking every parameter of the refrigeration cycle — from the choice of fluid to intelligent control — companies can significantly reduce their energy consumption, operating costs and environmental impact.

Frigotec, with its Belgian expertise and commitment to sustainability, supports manufacturers in this transition to high-performance refrigeration solutions. Thanks to its innovative approaches, high-efficiency equipment and specialised maintenance services, Frigotec guarantees installations capable of maintaining a COP greater than 5 throughout the year, even in Belgium’s variable climatic conditions.

Thus, the thermodynamic optimisation of refrigeration plants is much more than a technical challenge: it is a major energy and economic strategy for Belgian industry, a smart investment in a greener and more efficient future.

Leave a Reply

Want to join the discussion?Feel free to contribute!